Introduction

This 2 day internationally recognised training program is designed for those people who require working understanding of the techniques and principles of Lean 6 Sigma.Duration

2 Days, 9.00-16.00 (including an exam on day 2)Who should attend?

Lean Six Sigma is used across all sectors and all different sizes of business.

- Manufacturing

- Health Services

- Financial Services

- Retail

- Government Services

- Education

- Oil and Gas Services

- Logistics and Supply Chain Services

Lean 6 Sigma Yellow Belt dives deeper into Lean tools and techniques and starts looking into Six Sigma methodologies (DMAIC) and is intended for those who would assist and participate in process improvement activities. This can include workers who physically work on the job, after all who knows better that the person / people using the process day in, day out?

The ‘Yellow Belt’ would normally assist the Green or Black Belt who are usually the project lead.

Course objectives

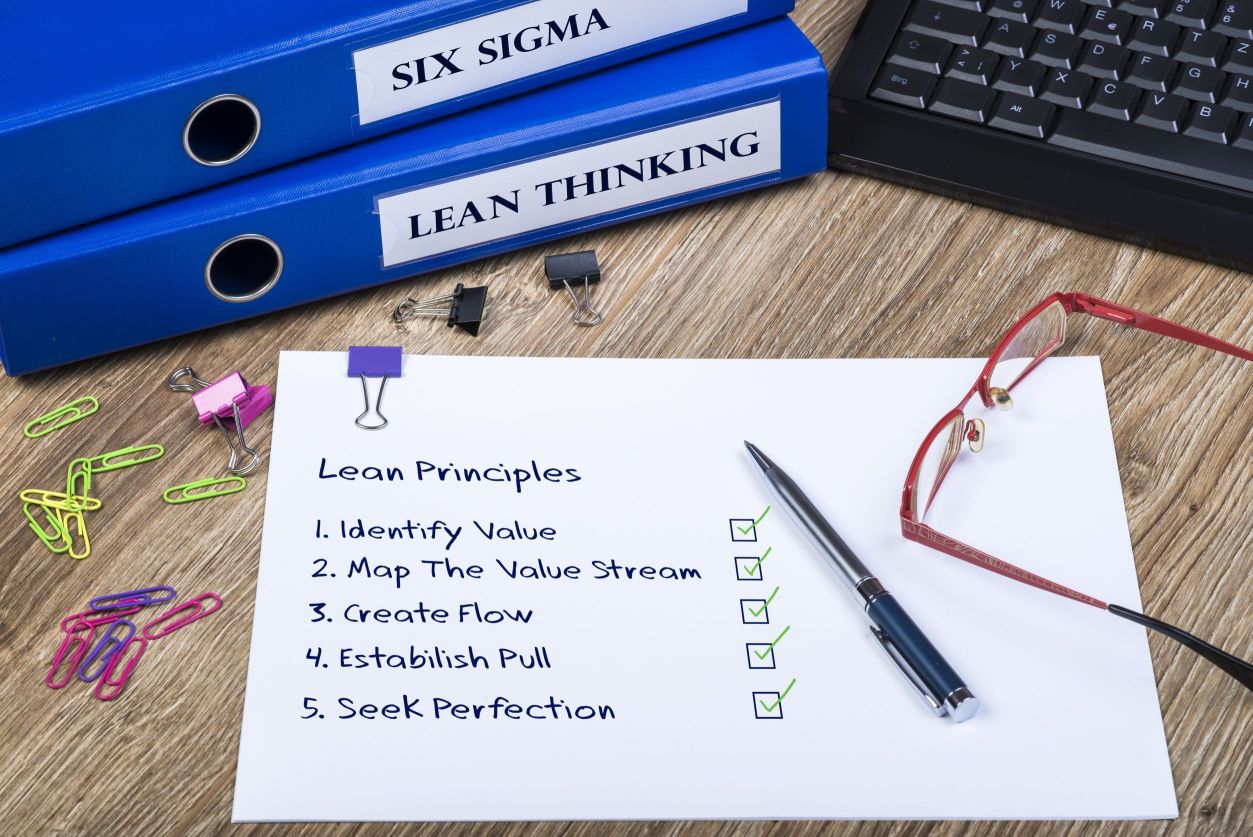

Lean Six Sigma provides a comprehensive and proven approach for the positive transformation of any organization by using the principles, methods, tools, and techniques to improve the key processes that make up the organization.

Lean Six Sigma specifically offers the following benefits:

- Improved Quality of products and services

- Lower amounts of defects, scrap, and rework

- Improved delivery times

- Reduced waiting times

- Reduced costs

- Improved customer satisfaction

- Improved employee morale

Course content

- Recap basic tools covered in White Belt – Delegates DO NOT have to complete White Belt to commence Yellow Belt as all topics are covered

- 5s, 8 Wastes, Visualization, Standardization

- Kaizen Activities / Plan, Do, Check, Act (Adjust)

- Process flow / Value Stream Mapping

- Introduction: Define, Measure, Analyse, Improve, Control (DMAIC)

- Benefits of data driven decision making

- 7 Quality Tools